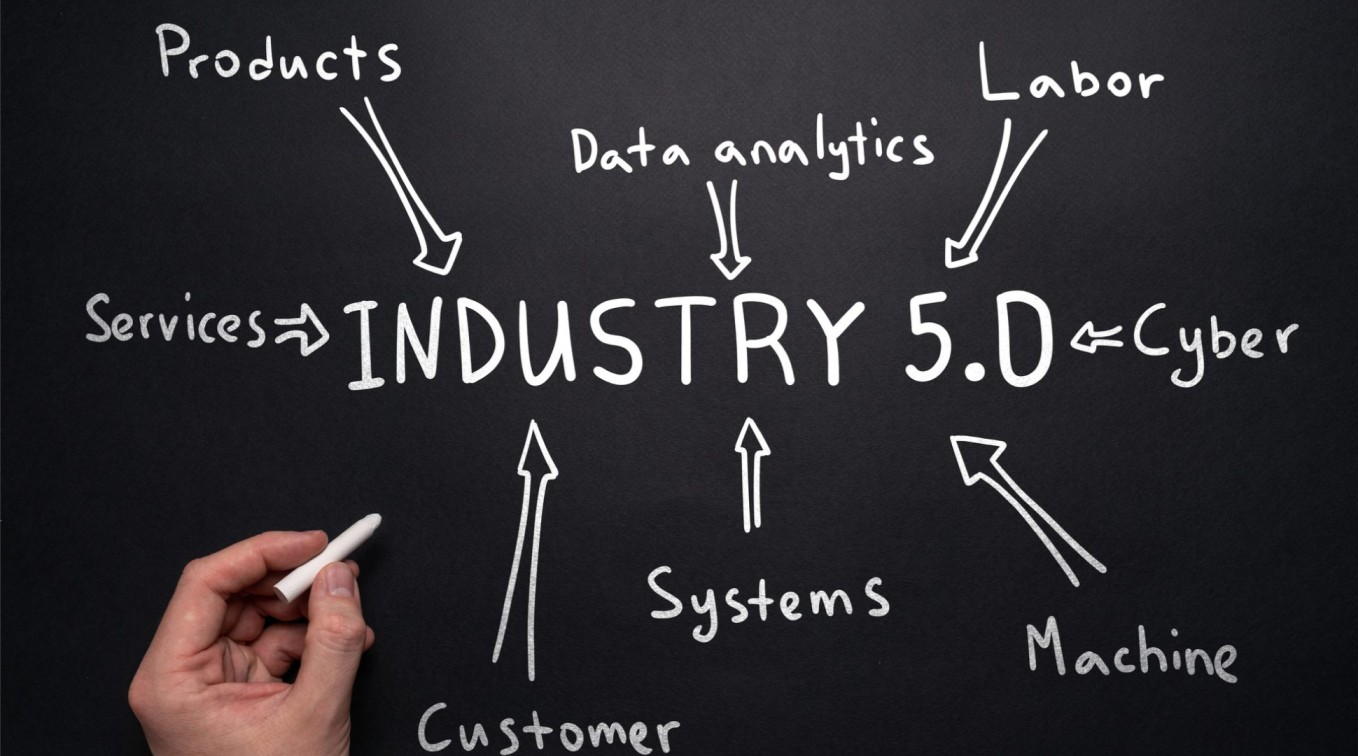

From 4.0 to 5.0 ... what changes?

Industry 5.0 is not only a technological revolution but also and especially a cultural one.

Digitisation and automation of production processes, already the cornerstones of Industry 4.0, are in fact complemented by human-machine integration with a view to quality of life and environmental sustainability.

Not only digitalisation but also greater collaboration between humans and advanced technologies to achieve:

• Worker wellbeing – Improved quality of work life by reducing monotony and burdensome workloads through intelligent automation;

• Eco-sustainability – Minimising waste and the environmental impact of processes.

Let’s talk about funding

The Transaction 5.0 measure, just like the 4.0, favours the path of companies towards human-machine integration and energy sustainability through a tax credit.

All companies based in Italy can benefit from this credit which, between 1ˢᵗ January 2024 and 31ˢᵗ December 2025, will see investments aimed at improving energy efficiency.

To access the contributions, you must:

- Invest in tangible assets functional to the technological and digital transition or intangible assets (such as software that guarantees the collection, data processing and continuous monitoring of consumption) in accordance with the provisions of Annex A and Annex B of the Transition 4.0 plan.

- Certify that the investment made translates into a reduction in energy consumption.

- Quantify the energy savings (which must be at least 3% on the entire production structure or at least 5% if calculated on the individual production processes).

Industry 5.0, with On.Plant it is possible

On.Plant, our software suite dedicated to the digitisation of Operations, provides access to these facilities.

Thanks to the combination of software dedicated to manufacturing, On.Plant makes it possible to automate, coordinate and balance all production activities, collecting data from machines, dialoguing with operators and lightening their workload.

With iOTTO, you consume less and consume better

In terms of environmental sustainability, one of the most complicated issues, we can provide you with a tool to reduce consumption and quantify energy savings: iOTTO.

Is our IoT platform for the control and energy efficiency of all industrial processes.

Thanks to iOTTO, you can:

- Improve energy performance, achieving results with fewer resources, reducing the costs and consumption of energy sources

- Monitor energy performance indicators, control consumption and implement complete and constant supervision

- Calculate the weight of the energy component on production costs, plan energy loads and automatically control the plants through advanced monitoring

In short, is the perfect tool for reducing production-related consumption and, being necessary for accessing Industry 5.0 contributions, quantifying actual energy savings.